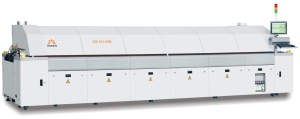

HTC-613D Semiconductor Vacuum Oven-3 Cooling Zones

The air transport adopts microcirculation, and the temperature difference inside the zones is smaller.

The equidistant PCB-push structure is adopted, and there is no sensor inside the hood to limit the product distance, which can realize soldering under high-temperature.

| Basic parameters | |

|

Models |

HTC-613D |

| Dimension (mm) |

L6300*D1450*H1560 |

|

Weight |

APPROX:3100KG |

| Number of heating zones |

Top 6/ bottom 6 |

|

Number of cooling zones |

Top 3/ bottom 3 |

| Cooling method |

Forced ice cooling |

|

Exhaust requirements |

10m3 /H*2 |

| Void rate |

APPROX:1%-2% |

| Control system | |

|

Power requirements |

3P 380V 50/60Hz |

| Total power |

64KW |

|

Segmented starting power |

35KW |

| Power consumption |

APPROX:13KW-18KW |

|

Hot air blower speed regulation |

Inverter stepless speed regulation |

| Heating time |

APPROX:30min |

|

Temperature control range |

Room temperature ~ 400 °C can be set |

| Production recipes |

Multi-combination production recipes can be stored |

| Transportation | |

|

Number of lanes |

Single lane |

|

Rail structure |

3-segment combined structure |

| Pallet dimension(mm) |

L330*D330 |

|

Conveyor height(mm) |

900±20 |

| Mode of conveying |

Isometric board-pushing |

| Vacuum system | |

|

Minimum vacuum pressure |

0.1Kpa |

| Vacuum pump flow |

APPROX:1000L/min |

|

Pressure relief time |

≤10s |

| Production efficiency |

≥40 s |

| Optional nitrogen system | |

|

Nitrogen structure |

Full/partial nitrogen filling |

|

Nitrogen system |

Automatic |

| Nitrogen consumption |

APPROX:300-500L/min |

Be the first to review “HTC-613D Semiconductor Vacuum Oven-3 Cooling Zones” Cancel reply

Related products

Semiconductor Series

Semiconductor Series

SMT Series

SMT Series

Semiconductor Series

SMT Series

Reviews

There are no reviews yet.