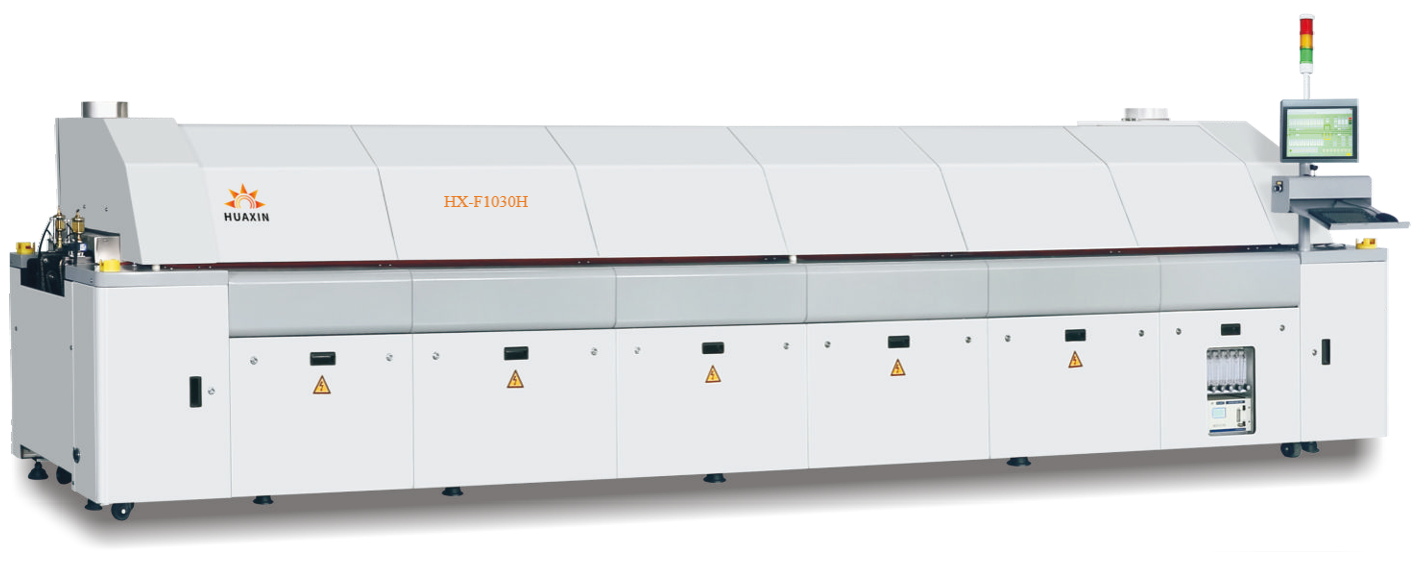

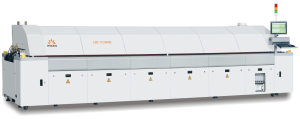

HX-F1030H Vacuum Reflow Oven

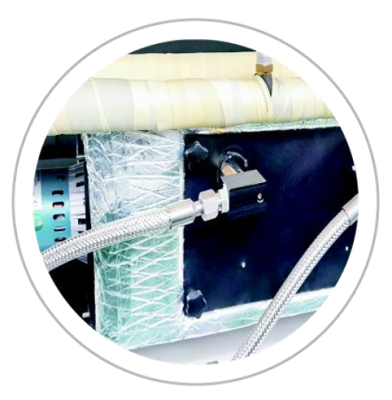

Flux collection system for easier maintenance and cleaner hood.

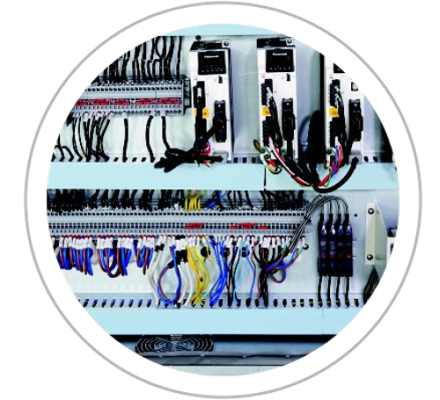

This equipment adopts embedded control system, with dual CPU calculation, can run independently from the computer (computer crash), not only stable & reliable, but also with more accurate temperature control.

| Basic parameters | |

|

Models |

HX-F1030H |

| Dimension (mm) |

L7100*D1430*H1630 |

|

Weight |

Approx.:3300KG |

| Number of heating zones |

Top 10 /bottom 10 |

|

Number of cooling zones |

Top 3 /bottom 3 |

| Cooling method |

Forced water cooling |

|

Exhaust requirements |

10m3 /H*2 |

| Void rate |

APPROX:1%-2% |

| Control system | |

|

Power requirements |

3P 380V/220/480 50/60Hz |

| Total power |

74KW |

|

Segmented starting power |

40KW |

| Power consumption |

Approx:12-18KW |

|

Hot air blower speed regulation |

Inverters |

| Heating time |

APPROX:30min |

|

Temperature control range |

Room temperature ~ 300 °C can be set |

| Production recipes |

Multi-combination production recipes can be stored |

| Transportation | |

|

Rail structure |

Single lane |

|

Vacuum structure |

Single chamber |

| Pallet dimension (mm) |

L400*D400 |

|

Conveyor height (mm) |

900±20 |

| Mode of conveying |

Chain drive |

| Vacuum system | |

|

Minimum vacuum pressure |

0.1Kpa |

| Vacuum pump flow |

1500L/min |

|

Pressure relief time |

≤10s |

| Production efficiency |

≥40s |

| Optional nitrogen system | |

|

Nitrogen structure |

Full/local nitrogen filling |

|

Nitrogen system |

Automatic/manual |

| Nitrogen consumption |

Approx.600L/min |

Be the first to review “HX-F1030H Vacuum Reflow Oven” Cancel reply

Related products

Semiconductor Series

SMT Series

SMT Series

SMT Series

Semiconductor Series

Reviews

There are no reviews yet.